One can expect to replace a hoist kingpin assembly every 5-7 years. Maximize the life of these parts, reduce costly maintenance, and reduce the chance of a breakdown while on the road. Read on for preventative maintenance and our innovative Hicks design versus competitors' hoist kingpin assembly.

Preventative maintenance.

-

Keep your trailer and parts clean.

-

Schedule a weekly disconnect and inspection.

-

Look for points of wear; hoist saddle cracking and abrasive wear on sliding surfaces.

-

Grease is the word! Lubricate parts every time you disconnect.

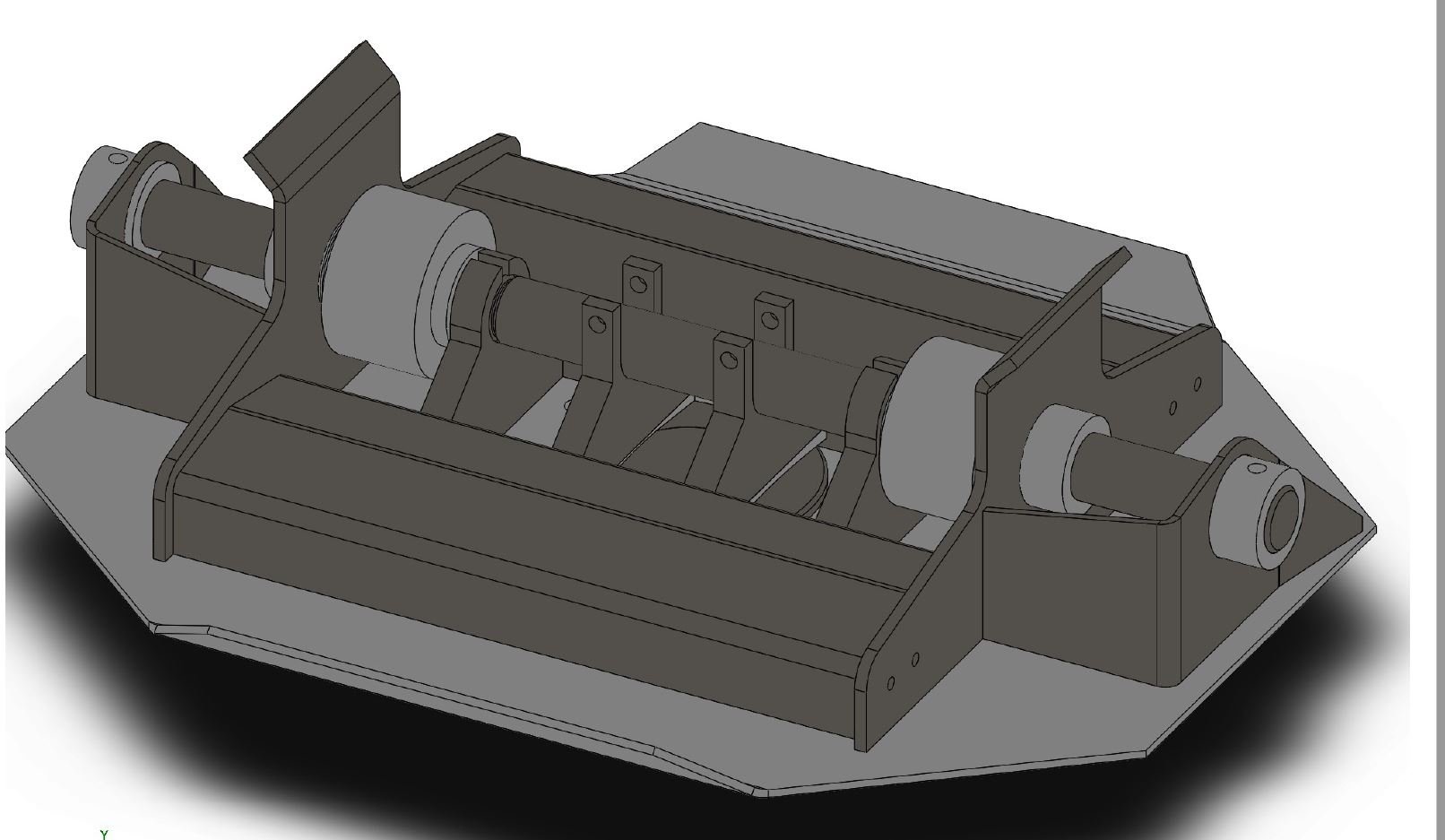

Hicks's innovative hoist kingpin assembly.

-

Innovative design reduces overall weight.

-

Hicks kingpin plate has rollers to support the body. The assembly is designed with easy, less costly wearable parts that prevent wear on hoist saddles. The hoist housing saddles the roller in which a greased pin moves. The roller and pin take the brunt of wear - no saddle wear.

-

Rollers and pins can be replaced in an hour.

-

Hicks's kingpin plate has drain holes that allow moisture to drain and also provide access for grease guns to keep fittings lubricated.

Competitor hoist kingpin assembly.

-

Saddles wear against a fixed surface with no moving and forgiving parts, resulting in hours of costly maintenance/downtime when they must be replaced.

See a comparison.

.jpg?width=514&name=Hicks%20T6%20KP%20Roller%20(003).jpg)